Understanding Greenhouse Water Treatment

Growers need to quickly understand greenhouse water treatment systems because of the new Canadian legislation on nutrient water recycling. It dictates that all farms must “Find an effective and economical way for greenhouses to recycle 100 percent of nutrient-bearing water.” This means you should be running a closed loop irrigation system for your crop, where you are treating and recycling your collected wastewater. Some of the outlined goals of the Ontario Greenhouse Alliance program are simple…

Expected outcomes

- improve water conservation

- reduce or eliminate waste discharges

- increase greenhouse competitiveness

Together, we are committed to developing innovative technologies that will enable Ontario greenhouse growers to increase their ability to recycle the water we use in our advanced growing systems.

This kind of win/win outcome is good for the environment and good for the economy of Ontario.

With lots of positive outlooks stated above from the project’s chair – Rej Picard

Which Direction should Growers Take?

However, little instruction or advice is given on engineering a proper greenhouse water recycling system that is left to the grower to research and make an educated decision after looking at all the options in the growing industry. We have sourced some of the best articles on Ozone Sterilization and UV Sterilization from the top growing magazines and publications available to us today.

Why these sources?

Because above all else, they are backed by science, years of lab testing or real data from real growers done within a case study. They are Trusted Sources for a reason. They have done their homework.

Taking a Look at the Different Systems – Ozone Vs. UV

What is Ozone?

What is UV?

So pretty much right away we can see a CLEAR advantage of using Ozone for greenhouse water treatment from the statements above, why?

- UV works when water is in the UV chamber only, it can’t keep up to commercial flow rates for greenhouse injection

- UV only works if the water has no turbidity (cloudiness or haziness of a fluid caused by large numbers of individual particles)

- UV sterilizes contaminants so they can no longer replicate (Ozone is 100% pure sterilization)

What Are Greenhouse Publications Saying about Ozone Water Sterilization?

All that being said, there is one more MAJOR ADVANTAGE of using Ozone Sterilization over simple UV. In Greenhouse Product News, in one of their articles entitled, “Grower 101: Water Disinfection” they talk about using Ozonation as one of the viable methods for greenhouse water recycling. Here is a small snippet from that article,

Ozonation

Ozone is a powerful oxidizing agent used to disinfect drinking water, but unlike chlorine, ozone does not result in chlorinated by-products. It offers high kill rates on fungi, bacteria, and viruses. Ozone reacts quickly and has no residual capacity. It acts as a donor of electrons (hence oxidation) to other substances. After the donation of electrons, ozone is itself converted to oxygen.

Did you catch that last part?

After the donation of electrons, ozone is itself converted back to oxygen.

That’s right after you completely disinfect your greenhouse irrigation water, the ozone itself converts back to oxygen. Oxygen is the life-giving source of all living things. Don’t believe me, try going into a room without any oxygen and tell me how long you last. What’s the point? Oxygen has a serious growth benefit for greenhouse crops.

All growers know they need a system to avoid root diseases and ward off any viruses in the water, but wouldn’t it be great if that system also had the benefit of increasing the crops yield and overall health?

Understanding The Benefits of Dissolved Oxygen for your Crop

The following information was originally posted from Grower Talks by Kurt Becker, where he discusses all the benefits of dissolved Oxygen in irrigation water.

Even the non-technical growers have an understanding and appreciation for the measurements used in greenhouse growing today. Monitoring and optimization of pH and Electrical Conductivity (EC) have become standard practice, improving plant health and quality throughout the industry. By measuring these two simple factors, most nutritional problems can be avoided.

The measurement of Dissolved Oxygen (DO) is also proving to be just as critical to plant growth. As with the other two measurements, there are minimum levels required for a healthy plant.

Also, by optimizing DO, as with pH and EC, we can see great improvements in plant growth and quality. However, far fewer growers are utilizing, or are even aware, of this measurement. Many of the practices in botany already consider the effect that oxygen has on the root zone. In the field, we till the soil. Among other things, this adds air space to provide oxygen to the roots. In horticulture, growing media is selected with a consideration for porosity for the same reason.

The benefits of oxygen to plant roots, and to the rhizosphere in general, is well established in the mind of the grower. However, most are unaware of the level of oxygen contained in their irrigation water and don’t realize that there are methods to improve this level.

So here it is pretty plain to see what Kurt is saying, “Hey Growers! Oxygen is great to have at the root zone of your plants” don’t you think that we should start to monitor and improve the level of DO in the irrigation line?

Let’s Read on:

Dissolved oxygen is simply the amount of oxygen (O2) dissolved in water. It’s one of the best indicators of the quality, and the life-supporting ability, of water. People need the right amount of oxygen in the atmosphere to survive. And, just as fish need the right amount of dissolved oxygen in the water to survive and thrive, so do plants.

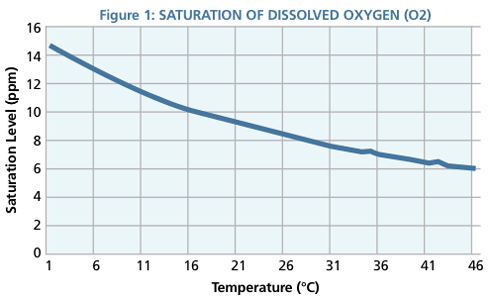

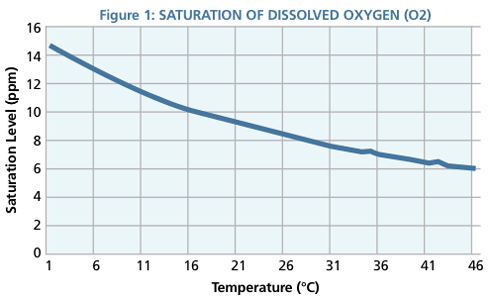

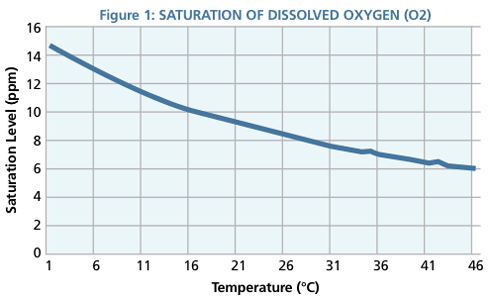

Measured in mg/l, as a percent of saturation (%) or in parts per million (ppm), dissolved oxygen levels are affected by the temperature and salinity of the water, and also by other chemical and/or biological demands (COD/BOD) of the water. Cold water can hold more dissolved oxygen than warm water (see Figure 1) and freshwater can hold more dissolved oxygen than salt water.

The maximum amount of DO that the water can hold is called the saturation value. It’s possible, and very often desired—especially in a greenhouse—to exceed the natural saturation point of DO in water. This is called super-saturation.

At levels around 5 mg/l of dissolved oxygen, irrigation water is typically considered marginally acceptable for plant health. Most greenhouse crops, however, will perform better with higher levels. Levels of 8 mg/l or higher are generally considered to be good for greenhouse production and much higher levels, as high as 30 mg/l or more, are achievable and can be beneficial. If the DO levels are below 4 mg/l, the water is hypoxic and becomes very detrimental, possibly fatal, to plants and animals.

If there’s a severe lack of DO, below around 0.5 mg/l, the water is anoxic. No plants or animals can survive in anoxic conditions. The irrigation water in many greenhouses has surprisingly low levels—often in the dangerous hypoxic range.

Unfortunately, without measurement and awareness of the dissolved oxygen in greenhouse irrigation water, problems caused by hypoxic water in plant growth often go undiagnosed or misdiagnosed. Happily, monitoring DO is fairly easy. Just as with pH and EC meters, there’s a wide range of devices available at varying quality, accuracy and ease-of-use to test the level of dissolved oxygen in the water.

We Now know 3 things for sure…

- We need to recycle our greenhouse wastewater (it’s the law)

- We need a 100% effective wastewater recycling system that works

- Ozone is far superior to UV for sterilization because it has a serious growing advantage by adding Oxygen to the water, plus its more effective

So how are we going to meet our list of must have’s for our farm?

Ozone Pro™ Water Sterilization For Greenhouses

One crop loss could cost 10x more than the amount to install and operate a disinfection system. Water disinfection ensures that plant pathogens are not being transmitted along with the irrigation water. Collecting and recycling your irrigation water will save you money on both fertilizer and utility costs. This is why we have created the Ozone Pro Water Sterilization System.

Benefits of Installing an Ozone Recycling System:

There are a number of advantages to using automated fertigation with an Ozone Recycling System for your greenhouse…

- Increased absorption: Plants fed with a fertilized irrigation system are better able to absorb the water, oxygen, and nutrients that they are being fed right at the root zone of the plant.

- Reduced feeding: Nutrients can be added to the water in micro-doses and the recycled water needs fewer chemicals to stay in balance. This, in turn, reduces the number of fertilizers needed and watering required. Placing fewer additives into the system reduces the overhead cost of fertilizer spend.

- Reduced waste: Ozone Purification reduces the amount of fresh irrigation water needed to irrigate the crop. There is very little runs off, evaporation, or wastewater being dumped. The closed-loop system eliminates a lot of water costs.

- Reduced risk of disease: Waterborne diseases and bacterial problems are extremely common. The content of the water is subject to whatever is existing in the line, where pathogens can thrive. Many organisms that can inhibit proper plant growth and can be very difficult to sterilize or neutralize by UV. Automated Ozone Water Sterilization eliminates 99.999% of all bacteria and pathogens in the irrigation line and the possibility of contamination altogether.

If you are interested in learning more about our commercial grade greenhouse water treatment systems please contact us from our website form.