Currently, in Canada, it is legal to produce distribute and sell marijuana for medical purposes under federal license. We’ve provided Greenhouse Growing Solutions for corporations, organizations and individual medical marijuana growers for many years and have assisted companies in getting the right greenhouse automation systems in place to help them thrive in business.

Not Only Medical Marijuana, but All Marijuana will be Legal by 2018

The Next 600 Million Dollar Industry.

The legal medical marijuana business is growing rapidly, offering potential riches to savvy entrepreneurs who get in at this early stage, says Huffington Post Canada. But for most growers, a major obstacle stands in the way. The indoor systems they use require massive amounts of energy–and, in turn, money–to keep running. But how do new Growers get set up and grow efficient as to stay profitable?

What is The Solution?

Getting The Right Medical Marijuana Growing System

Climate Control Systems Inc. has been manufacturing top quality greenhouse automation systems and providing world-class growing solutions for commercial growers since 1983. We work with you to provide the perfect environment, with a focus on fertilization and clean water for a consistent cannabis crops at maximum yield, from greenhouse climate management to our fertigation systems and our new Ozone Pro Water Purification Systems all help marijuana grower to provide the best growing environment from lighting to root health and all aspects of environmental controls, including circulation. Our dedicated marijuana grow team can assist you in setting up a successful growing environment and help with project management of your medical marijuana greenhouse or cannabis farm using advanced automation technology and over 35 years of experience.

Know this!

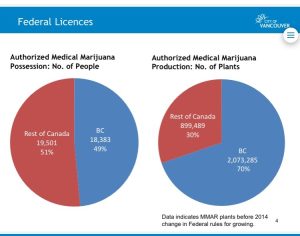

There is going to be a HUGE demand for not only Medical Marijuana but if the legislation goes through for deregulation of pot, there will few growers in place to keep up with that kind of demand. Licensed growers now are having a hard time keeping up with the demand from medical doctors prescribing marijuana to patients alone.

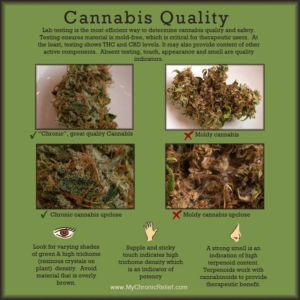

What is Really Going to Make the Difference in Growing Top Quality Medical Marijuana?

Not only will supply and demand be an issue, quality will be a #1 concern to the Government of Canada. After all, we are talking about dispensing this ‘new medicine’ to sick patients. While some greenhouse equipment consultants and other advisors would like to believe the entire success of a grower is due to the greenhouse system or type of greenhouse structure you have in place, this is just not 100% true. Top quality growers will grow top quality plants, and poor quality growers will grow poor quality plants. What the right greenhouse automation system and control technology will do is make it easier for good growers to grow top quality cannabis, in a couple of ways.

Plant quality generally goes up with proper use of high-tech greenhouse control because the automation reduces human error variables. In this way, our technology watches over your crop ensuring that each stage of growth is productive and you are fully able to get the benefits of becoming a new Medical Marijuana Grower.

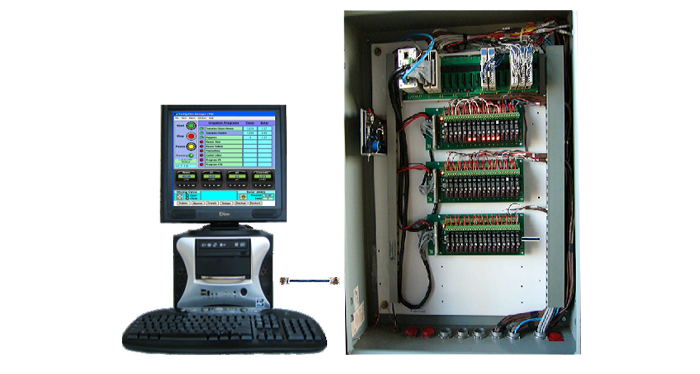

Medical Marijuana Greenhouse Automation Technology

At Climate Control Systems we help growers automate and control all the elements in their cannabis greenhouse or medical marijuana growing facility for the best plant growth possible in the industry. For cannabis growers we integrate sophisticated computer controlled greenhouse systems saving growers a lot of time and money on energy costs and fertilizer. We have advanced greenhouse automation technology that can control grow lighting, air vents, CO2, and heating and cooling when required and all from a smart phone or tablet.

We provide computerized greenhouse automation and controls to integrate a complete holistic growing system with all the requirements for each strain you grow, different feed configurations can be set up with ease, and plant health can be monitored by anyone with internet access, ensuring your growing environment is productive year round.

12 Ways How our Greenhouse Automation Helps Cannabis Growers like You.

- Helps to Lower Water and Energy Costs

- Exact Fertilizer Calculations and Manage Water Usage

- One Central Machine for Multiple Crop Feeds

- Customized To Your Needs with Sensors & Injectors

- Fully Expandable to Continue to Grow with your Greenhouse

- Software Greenhouse Technology that is Responsive

- Updates and Upgrades to Software Versions

- Substrate moisture sensing with conductivity

- Temperature Monitoring and Control

- Co2 Levels in each Greenhouse Compartment

- Fan, Co2, HID lighting, shading, fog and pad control

- Irrigation and misting programs with VPD (vapour pressure deficit)

Our Engineers work closely with you the grower to ensure maximum production of the marijuana plant, whether you’re growing in a greenhouse, or larger warehouse facility. The rising number of light deprivation greenhouses or hybrid greenhouses are on the rise as growing facilities in Canada. In fact, this article states that going the greenhouse route is a smarter idea, than using warehouses or just outdoor growing, due to the energy cost in producing marijuana. Energy and Labour costs are always going to be the number one expense of a grower and any system that you can put in place to help you save in these areas, is money well spent.

Don’t believe me? Just have a look at this article…

A growing number of cannabis producers in Canada are using greenhouse space for a lower operating cost and a smaller carbon footprint.

While the majority of licensed producers in Canada grow cannabis in an indoor setting, there are a growing number of secure greenhouses of all sizes being approved for production under the MMPR. Currently, 5 of the 20 producers licensed to sell cannabis for medical purposes are growing ‘under glass’, as are several others at various stages of the Levantine application process.

Greenhouses offer a smaller carbon footprint, but also a corresponding decrease in operating cost, by some estimates up to 90% lower hydro/electrical costs. Not only do the numerous lights used in an indoor operation draw an enormous amount of power, but the subsequent heat these lights generate then needs to be cooled with massive and costly air conditioning systems. The cost of lighting and cooling a typical indoor MMPR facility can range from $5-10 per sq ft per month, depending on size and region.

Medical Marijuana Started in our own Backyard

Aphria Inc. and Climate Cotnrol Systems Inc both located in Leamington, Ontario, the greenhouse capital of the world. Aphria was the first approved producer under the MMPR to begin growing in a greenhouse. With a current 20,000 sq ft footprint within a 450,000 sq ft existing glass structure growing ornamental flowers, Aphria currently represents the mid-sized producer, but has the potential for a much larger scale. They are currently in the process of expanding their footprint by another 20,000 sq ft and are awaiting final Health Canada approval for this new space.

Aphria is run by Cole Cacciavillani and his partner John Cervini, who have been growing food and flowers in this region for decades, and their approach to cannabis is a stark contrast to many indoor facilities one comes across under the MMPR. While their drying, processing and packaging rooms sit inside their 600 sq ft vault and feel more like the typical indoor LP, their 3 large greenhouse rooms full of cannabis very much feel like a typical agricultural operation.

Interested In Learning More About our Automation Systems?

If you are just getting started in medical marijuana or are a seasoned veteran let Climate Control Systems, help every aspect of your cannabis crop and save more money and energy with advanced greenhouse controls. We listen to the customer to ensure what is delivered is nothing short of World Class Greenhouse Automation.