Automation Can Help Marijuana Greenhouse or Indoor Cannabis Facility

Getting a Marijuana Greenhouse Automated & Fully Operational.

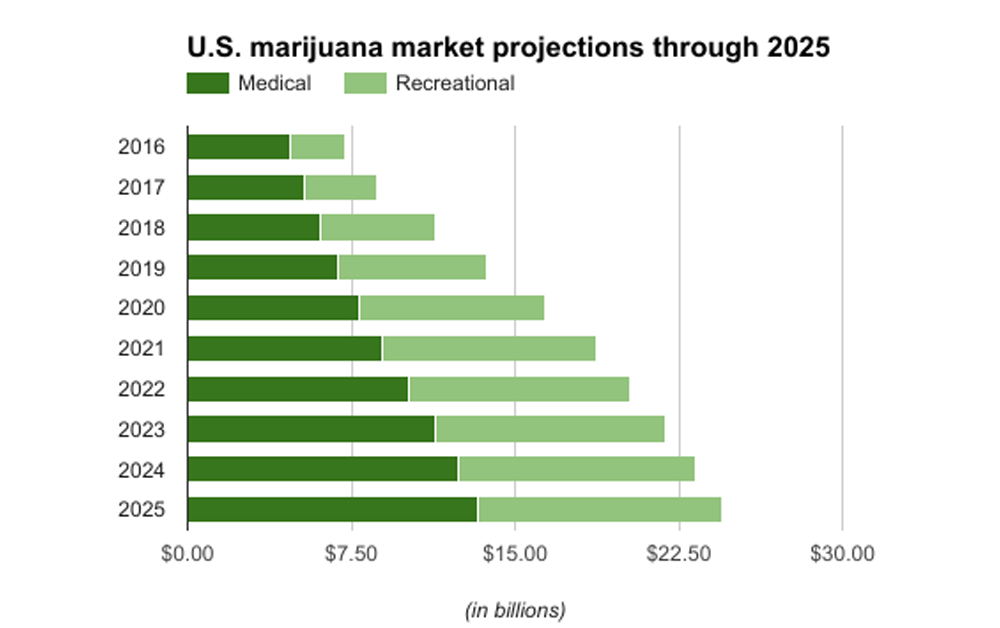

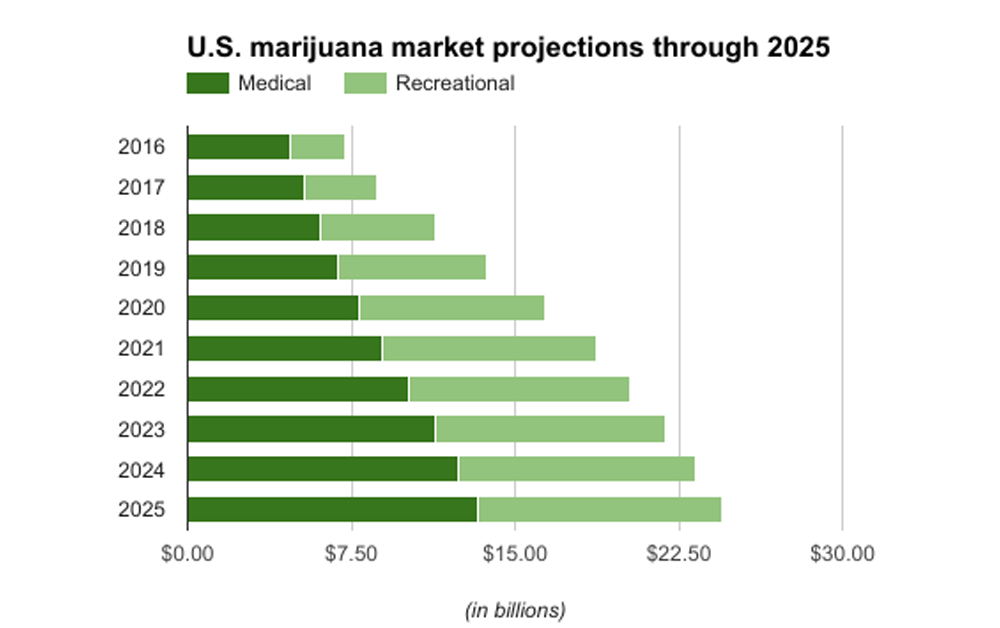

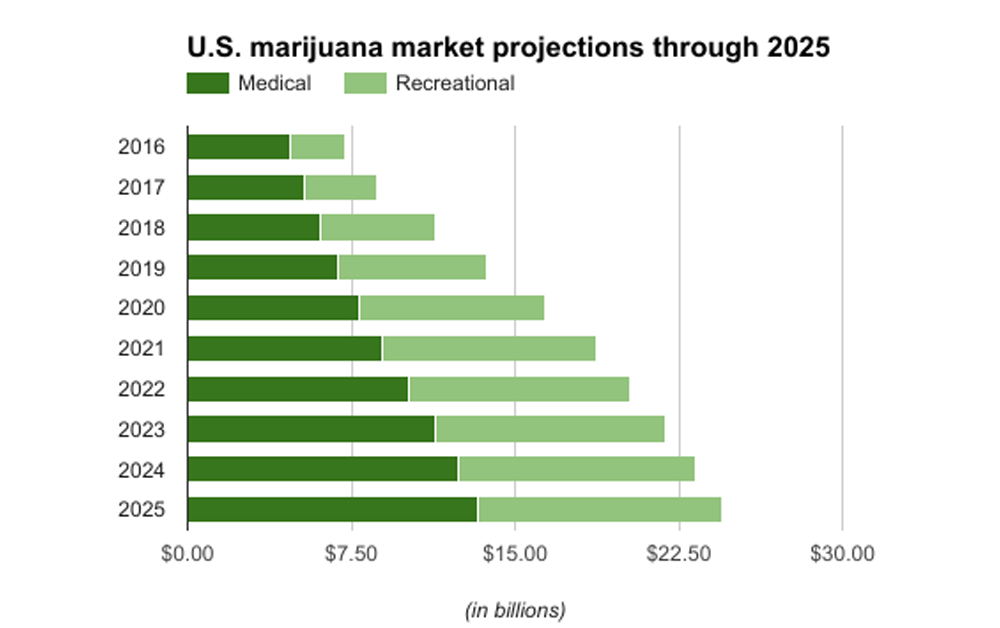

With a good deal of marijuana greenhouse growers, automation companies and new investors are teaming up to get the best out of what has been called the next “green rush”. You can be sure of one thing, there has been serious advancements in innovation and how growers are controlling an indoor cannabis facility. There is no doubt just how lucrative these projects can be, but how does a grower stay ahead of the competition? Have a look at some projected numbers for the US marijuana market projections for medical and recreational use. The numbers are to exceed 8 billion in 2018, says thecannabist.co a popular news column on everything cannabis.

But how does a traditional or new grower break into the market and start to grow successfully through time?

This is where Climate Control Systems Inc with 35 years of automation & growing experience can become helpful. More economical and environmentally friendly methods of production are being developed, but there has been a heavy shift in growers to invest in controls & automation. This makes sense when you know and understand that automation can increase production and crop yields, while lowering labour & utility expenses.

Greenhouse automation for cannabis growers, adapted from other growing operations previously, provides amazing results. The closed, or sealed, greenhouse can create the perfect conditions for maximum benefit to your cannabis crop if you are effectively controlling the internal greenhouse environment in all stages of growth. This is key as stated by many of the largest commercial cannabis growers in the industry. An indoor cannabis facility is similar with a more warehouse type environment. In both cases keeping the growing conditions at a constant optimum level is going to the path to success.

Read this quote from one of the largest medical marijuana growers in North America.

Cole Cacciavillani from Aphria Inc. says in a recent video, that “Our environments here are all computer controlled and that gives us the flexibility to keep that environment the same, day or night.”

With a large focus on automating Co2, Grow Lighting and the irrigation of the crops Climate Control Systems can handle all of your greenhouse automation needs.We help growers automate and control all the elements in their marijuana greenhouse or indoor cannabis grow facility for the best plant growth. For cannabis growers we integrate sophisticated fertigation systems that can be integrated with our Climate Manager to control grow lighting, temperature & humidity, air exchange, CO2 dosing, and misting and fogging where required. We even have new soil sensors for both soil and soilless media to read the temperature, EC and moisture at the root zone of the plants.

We provide computerized automation controls to integrate the entire growing system with all the requirements for each strain based on bench, or room configurations, automating your complete internal growing environment.

Because Cannabis is an industry in its early stage we understand that you may need to start with a modest size operation but be rest assured our automation systems can be scaled as you continue to grow your cannabis business.

One of the challenges medical marijuana growers face lies in providing consistent product, from seed to sales. Medicine requires the same results with each dose and often times has to be certified to be sold. Consistent, specific growing conditions are imperative to that goal. Automating your systems will control temperature, lighting, water, nutrients, and ventilation, while eliminating costly mistakes. The automated system keeps historic records so that you can monitor growth patterns and repeat desirable results.

Medical marijuana growers must meet a number of quality standards. If you are one of these folks, you know how important it is to be disease and pest free. Automated systems take the mystery out of problems like root and bud rot, which occur with over-watering and high humidity. They do not interfere with your use of organic pest control, such as ladybugs and nematodes. Automated ventilation ensures that your crop is warm enough, cool enough, dry enough, and does not release noxious or obnoxious fumes for your neighbors to complain about.

Have a look at this, MTV’s Growing Exposed have produced some great media coverage on Rochester Farms a commercial medial marijuana grower in the US who is utilizing our automation systems to stay productive, save on utility costs and get a higher cannabis yield.

As you can see it is not a question of if your going to use automation or not, it is a question of which automation system to invest in. With over 35 years of growing experience and more than a few environmental and business awards, Climate Control Systems have helped hundreds of growers across the globe with both greenhouse automation and their indoor cannabis growing environment. If you have any questions or need an estimate on a system, talk to one of our greenhouse engineers from our contact page.

Indoor Cannabis Growing Facility Tips

To Seed or Not To Seed? That is a valid question. Since clones are produced by taking plant cuttings, they maintain the exact qualities of the parent plant without variation to the strain. Seeded plants will take on the characteristics of both parent plant and pollinator. There is no assurance that the resulting cross will be the same as the parent plant, whether the plant will be male or female, or if undesirable characteristics will be dominant.

Cloned plants develop roots and reach their vegetative state in about two weeks. Seeds may take as many as six weeks to sprout and a few more to reach the vegetative stage. Using full spectrum LED light cycles for 18 to 24 hours each day will allow you to speed up their growth cycles.

The automated indoor cannabis growing operation is ideal for the Sea of Green (SOG) growing technique. The SOG method uses minimal space and can speed up your growing operation by as much as seventy five percent. You can use either clones or seed plants for SOG growing, however nutrients flow better in green stems than through woody stalks. Clones take on better nutrition, producing more potent buds than seed plants. This allows them to produce healthier plants in a smaller space over a shorter time period, which, in turn, allows for more growing cycles to take place in a given year. Overall, cloning offers a much more efficient commercial grow up for cannabis.

Once your plants have gained about a foot of height, you will place them into blocks of soil or growing medium, and set them about a foot apart on specially designed rolling tables. The tables are designed as shallow trays so you can provide precisely calculated, computer controlled amounts of water and nutrients to the roots at appropriate intervals. At this stage, the lighting, also computer controlled, is changed over to a 12/12 cycle that forces flowering. As the bud canopy develops, you may trim lower branches of the plant and root them as new clones for the next crop.

Once the growing operation is complete and your plants have been harvested, a washing system tips the tables into an upright position, where they are disinfected, pressure washed, and sent back to start the process again.

Greenhouse automation for cannabis growers means that the plants are given the appropriate amount of lighting for each stage of growth. Irrigation and fertilization of the plants occurs on an optimal schedule usually on growing tables as shown in the above video. Heating and cooling are accomplished through the use of a closed ventilation system that provides fresh air exchange, keeps humidity at acceptable levels, and filters in-bound contaminants and out-bound odors. Systems of rolling tables allow you to easily move four foot by twelve foot trays loaded with plants. Being able to move entire blocks from section to section reduces man power and potential injury to plants or workers.

Putting the system on auto-pilot is actually an option these days. With an automated indoor cannabis growing operation, you can expect higher yields with consistent quality and lower operating costs, but the true beauty of an automated growing operation is in its complex simplicity.

With all environmental factors under computer control, very little human interaction is required so you can better focus on your business, leaving very little room for human error.

Our software programs are both responsive across many devices and allows you to monitor and make corrections in the system, should the need arise, right from a tablet or smartphone. With a totally automated commercial grow operation for cannabis, you can take increase year end profit margins.

Here is to a better way to grow medical marijuana by controlling the greenhouse environment with automation, get in touch here.