As the pandemic makes us all think and we are reminded to shop local, the demand for locally grown produce is increasing at an exponential rate. Not to mention food security, the increasing trend to have a stronger plant-based diet. Vertical farming is becoming more practical with improvement from LED lighting being more efficient and considerably less money that just a few years ago. Having multiple racks with lighting is becoming much easier to build and maintain.

Buildings that were left unused for years are now finding new life as vertical grow operations start to fill empty retail and manufacturing locations, in malls, industrial areas and forgotten underground vaults to name a few.

Whether you are using the latest in rolling racking or re-purposed industrial racking, racks are going up from 2 levels tall to 15+ levels tall of growing space.

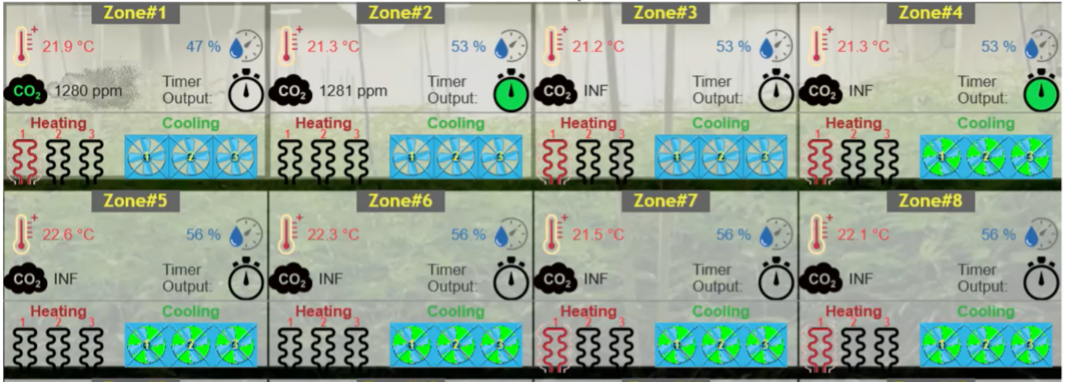

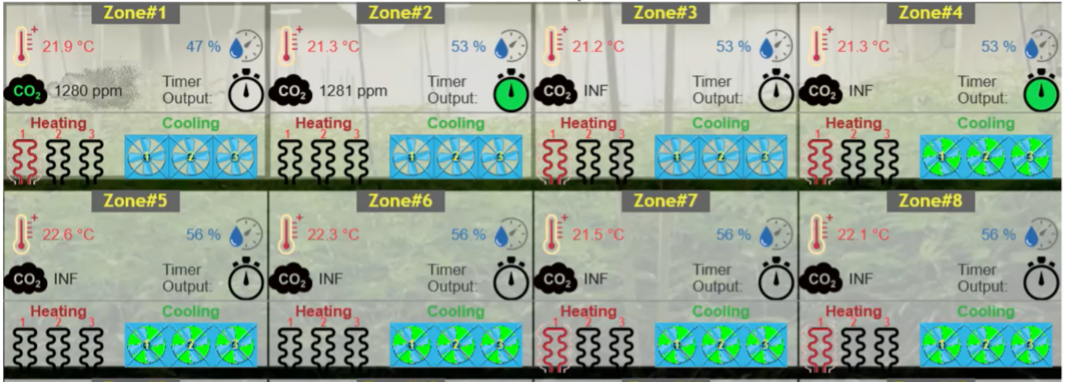

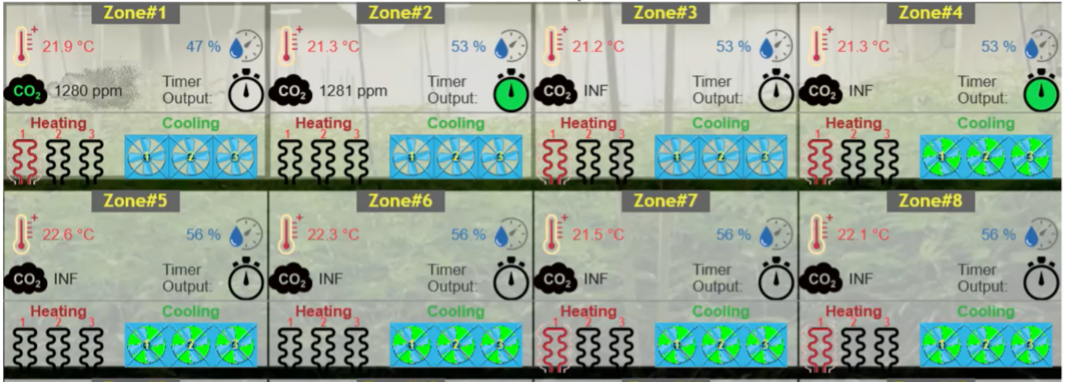

Controlling the environment in these areas is as critical as it is in the modern greenhouse, with plants being grown closer together the risk of disease spread is greater so keeping the air fresh with just the right Vapour Pressure Deficit (VPD) is even more critical. If the VPD is too high or too low your plants won’t be able to feed and grow properly. A vertical operation can create many microclimates within a grow single room, so it is important that your climate control equipment is able to monitor and control many areas of the grow benches from low to high, front to back.

Climate Control Systems’ Climate Manager does just this, monitoring and adjusting multiple zones with temperature, humidity and CO2 sensors controlling the HVAC equipment and CO2 control. The Climate Manager does this in real time and can control the VPD in your grow rooms. Having all this plus lighting schedules, running from simple on/off schedules to complex schedules, seeing your water tanks levels of fertilizers all controllable from your phone or tablet anywhere in the world with a full overview of your operation on the click of a thumb.

Water treatment, pre- and post-fertigation, along with proper fertigation are all other important aspects of a Vertical Grow Operation – which we’ll cover in a future post.