Automated Fertigation Control System For Medical Marijuana

Growers of various cannabis crops are realizing that they can get a serious increase in yield sizes by embracing an automated fertigation control system. Fertigation is a mixture of irrigation and fertilization into a single automated system.

This simple fertigation system takes the guesswork out of feed formulas and produces bigger, better plants. All of this can be set up by the grower, feed schedule and feed formulas for different medical marijuana strains in the greenhouse.

Any Cannabis Growers looking to reduce their fertilizer cost and water usage need an automated fertigation control system. These systems use wireless sensors to determine the temperature, E.C. and moisture level right at the root zone of the plant. It’s like knowing what you medical marijuana crop needs for irrigation and nutrients for each of your product strains.

This article provides everything you need to know about what these systems do, how they work, and why it is a money saver for your operation. Again, most growers report around a 30% savings in fertilizer costs and a 40% savings in their water bills. Our commercial fertigation systems will provide great value to marijuana growers in the way of ROI.

What’s an Automated Fertigation Control System?

Whether you are indoor grow cannabis facility or growing marijuana in a greenhouse, our automation systems can save you time and money.

Our latest Fertigation Manager software works to deliver steady water and nutrients to your crop with more efficiency. The increase in regularly scheduled feedings produces healthier plants and a much greater yield!

The system gathers information to inform growers on how best to fertilize and irrigate their plants. Sensors precisely measure the moisture level of your soil or substrates to determine when irrigation is necessary. You can also set up multiple triggers for the automation to start greenhouse irrigation. Everything is logged and charted so you know exactly where you are at with your fertilizers, liters or gallons of water fed out to the crop.

The Fertigation Manager

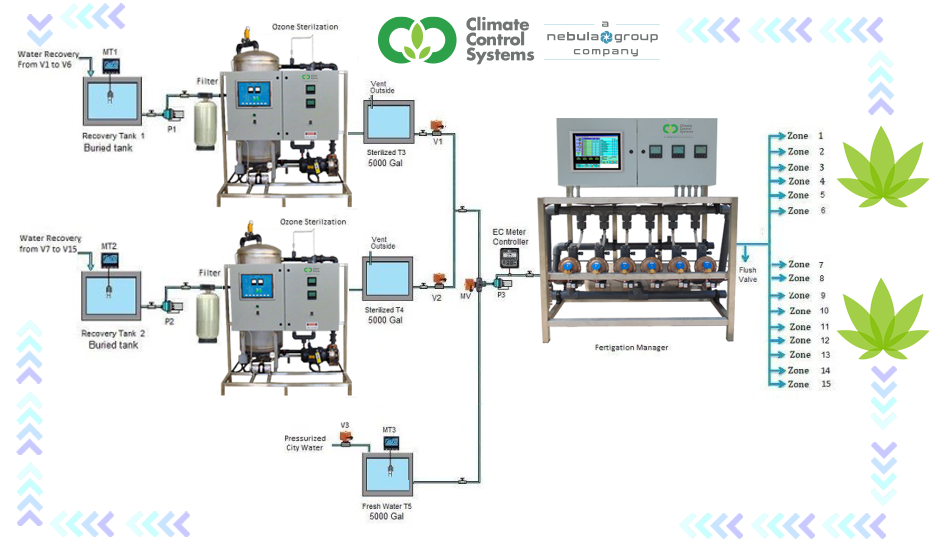

The Fertigation Manager gives you a readout of the E.C. Levels, Flow Rate, Ph, and E.C. of the return water so you know what the plant absorbed. A water pump moves the solution in the mixing tank through the system and out to the crop.

The Fertigation Manager serves as the central hub behind the automation. From your digital interface, the system allows you to regularly set the nutrients to water ratio and automatically mix it in the tank.

Pipes carry the nutrient solution from the Fertigation Manager out to the growing area. Place the automated fertigation system nearest to your inline water source, and use pipes to carry the feed solution to your greenhouse or grow op.

Pipes run the length of each plant row. Smaller rubber tubes connect to the pipes and carry the solution to each individual plant. In a drip system, a drip cap goes at the end of the tube to regulate the rate of irrigation. More often flood tables are used in Medical Marijuana indoor growing like shown in this video clip…

The wireless sensors get placed into the growing medium and each plant zone can be measured for moisture levels. They transmit the soil information back to the Fertigation Manager which automatically irrigates if or when the soil gets too dry.

The sensors also transmit information on the root zone EC levels, so you know exactly how much nutrients are being fed to the plant.

What are the Benefits of Automatic Fertigation?

Fertigating produces better crop quality than traditional practices. And at precise amounts of micronutrients which can deliver higher yields.

A benefit of using a fertigation system is the increase in plant health. Applying nutrient directly to the roots of the crop increases the efficiency by which the plant absorbs the feed solution. This also makes the crop more resilient to diseases.

Beyond the advantages to your crop, using a fertigation system is of benefit to your environment. Using fewer nutrients more efficiently means that less excess chemicals make their way into the groundwater. We have even produced a greenhouse water recycling system to handle all wastewater right on site. With new ozone technology in our greenhouse water treatment systems, you will never have to worry about your irrigation water again. Greenhouse water purification is a great way to stay on top of disease management and get rid of all pathogens living in the water.

Fertigation greatly reduces the amount of fertilizer contaminant that leaches into your surrounding groundwater.

Solid and granular fertilizers take time to dissolve into the soil and make their way to the roots. Fertigation systems employ a water-soluble nutrient solution. Fertigation systems pump the nutrient solution through pipes, directly to the roots of each plant.

The result is a big saving in the time you expand on the act of fertilizing. Our automated hydroponic system can read sensor data to determine when and how much to irrigate.

Fertigation increases the efficiency with which micronutrients that are delivered to the roots. It is also perfect for flood tables in medical marijuana for your nutrient dosing system.

Factors for Consideration

In order to determine how many nutrients, and with what nutrients you need to fertigate, perform a soil analysis test. Each fertigation program is specific to the existing content of the soil.

Also, perform a water quality test to asses the contents of minerals and the existence of sediments. Vegetables require the use of a drip system. Sediment in the water gunks up the tubes and drip head.

Make sure your system has access to enough water to properly irrigate your crops. Find a location for your control system that has access to a manmade or natural water source. If you are using water from a natural source, it is necessary to filter the sediment before it flows into your nutrient tank.

Your final consideration is the source of your fertilizer and its solubility. Dry fertilizer, whether its manure or plant compost, is not water soluble. Always use a compost-based fertilizer in a fertigation system.

The cheapest way to feed your plants is to make your own water-soluble nutrient solution. All you need is a healthy compost to use for the nutrients. This type of fertilizer is called compost tea.

Compost tea is cost-effective and regenerative to the soil. Compost tea is naturally full of the vital micronutrients that increase the plant’s ability to ability to retain nutrients and resist disease.

And, in an automated fertigation control system, studies show that compost tea improves plant growth, yield, and quality.

What Does the System Measure and Automate?

When it comes to automation, all systems differ on the extent to which it measures environmental factors. All systems test the soil moisture level and manage nutrient dosing.

Some systems integrate with facilities existing environment control unit to manage from a central location.

Automated fertigation control system monitors a range of factors across the system. A filtration system cleans the water with UV light, pasteurization, and filtering. Then sensors measure the level of the water in the tank, temperature, and Ph levels.

Sensors in the mixing tank measure the EC nutrient level and pH, adding acid or base as needed. Soil sensors measure moisture and over drainage to relay to the nutrient dosing equipment.

Pump controls and irrigation valves connect to the control system to be managed automatically.

Types of Fertigation Systems – Closed Looped

Greenhouses and grow facilities use two types of automated fertigation control systems: dilute tank control or in-line injection. Both methods achieve the same ends by different means.

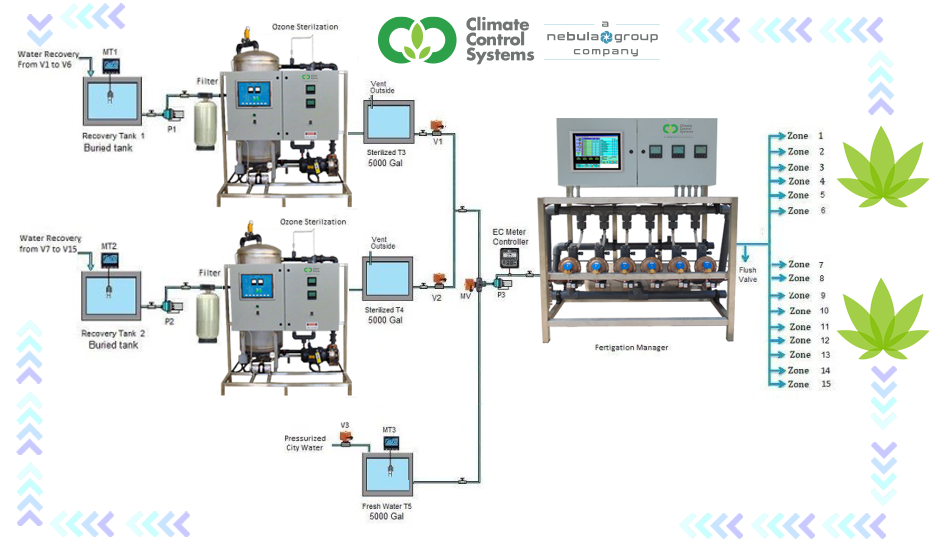

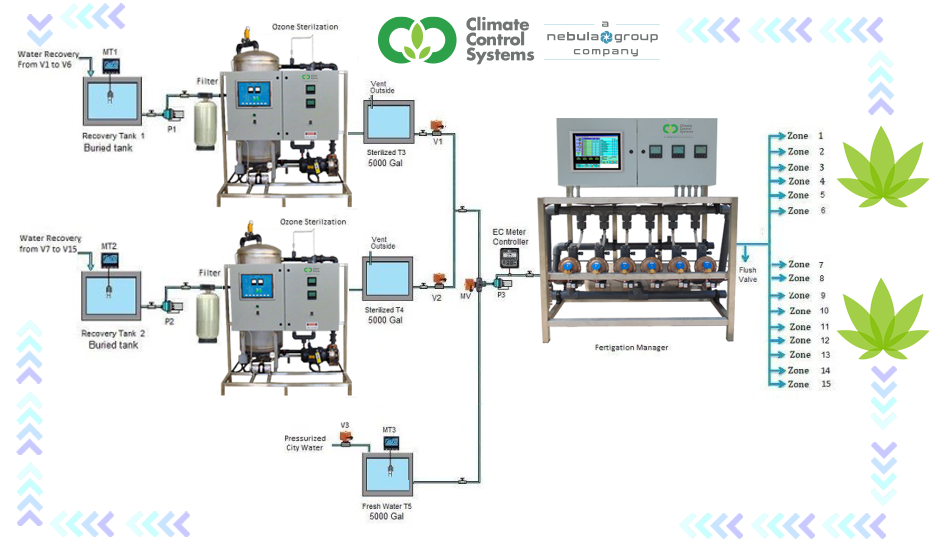

Closed Looped System: Fertigation System Diagram

Dilute Tank Control (Batch Method)

In a dilute tank control system, the nutrient solution and water mix together in large tanks and are stored. Growers mix the water to the nutrient ratio by hand for each tank, and they are sealed until needed. Dilute tank control systems are simple and easy to manage.

This system can integrate with automation control. An automated dilute tank control system separates the mixing process from the nutrient distribution process.

However, the downfall of this method is that mixing fertilizer batches by hand can be wasteful. Over mixing can change feed formulas or get expensive in the way of waste.

Another factor to consider is the storage space requirements for your tanks. For growing multiple plants of differing nutritional needs, a separate tank is needed for each variety. And you have to repressurize each tank before distributing the solution through the system.

Automated Pneumatic Injector System

Our Fertigation Manager Equipment is popular for larger growers because one system serves the needs of all your plants. In-line systems mix the nutrients to water ratio as-needed. No Waste.

The pressurized system works in real-time to meet the needs of any plant variety. The grower can customize feed formulas and see data on how much water was feed to the crop.

The fertilizers and chemicals are mixed in-line and are fully blending the right away. Our fertilizer injection system injects just the precise amounts of fertilizers to the crop, saving the grower money each time and resources you feed.

This system injects a concentrated nutrient solution into the blending tank in-line. The fertilizers get injected into the mixing tank, following the grower’s precise programmed recipe. The control unit measures the system flow rate, electrical conductivity, and sensor data to determine the proper injection volume.

Final Thoughts

A multi-crop grow facility benefits the most from this nutrient injection system, as you can manage multiple feed formulas for many strains of cannabis. Consider the space available for the Fertigation Manager and the variety of nutritional needs of your crops.

Integrating an automated fertigation control system with your facilities greenhouse environment controller enables the maximum potential from your crops yield. Automating your grow saves you money on nutrient, makes you money on revenue, and saves you time spreading fertilizer.

If you like this article about our automated fertigation control system, do us a solid and share it with a friend on social media.

If you need help with fertigation system design contact one of our greenhouse engineers here!