People in larger city areas are gradually starting to learn the importance of vertical farming. Urban farming has become an issue that needs modern solutions as growing crops inside of cities is not easy, considering the lack of space.

What’s the answer then? Vertical farming, of course!

Today, it is easier than ever to get better results from vertical farming with grow automation technologies. Meanwhile, being stuck inside the house during lockdown has taught everyone the significance of agriculture, pushing them to adopt better farming techniques, especially vertical growing systems, now more than ever. We have all seen how fragile our food supply chain can break down for various reasons. Having more food, even when we have less space to grow it in, is a major step forward.

Let’s find out more about urban farms, vertical farming and how Grow Automation with good metrics can help you.

1. Why is vertical farming better?

Growing food is gradually becoming a part of city life, thanks to urban farming. One of the best forms of urban farming is vertical farming. The best thing about vertical farming systems is that they facilitate agricultural activities inside buildings without worrying about space.

The benefits of vertical farming are as follows :

a) A vertical farm makes mass production of vegetables and herbs possible in a sustainable way.

b) The plantings are stacked on top of each other, making use of vertical space. This saves floor space required in traditional farming systems.

c) Vertical farming systems allow recycling. Thus, the use of water in vertical farms is almost 95% less. Hence, it is one of the eco-friendly solutions for growing plants.

d) As vertical farms can be set up indoors, there is usually no need for using pesticides, herbicides. etc.

e) It is possible to grow seasonal crops throughout the year with the help of vertical farming systems.

f) This farming facilitates the growth of crops using natural resources without depending on fossil fuels.

g) The water for irrigation can be recycled on premise and save you money

Who can benefit from vertical farming systems?

To be fair, a vertical farm can benefit everyone living in the city because agriculture is essential for everyone. If you have an interest in the food industry or a passion for farming, you can benefit from vertical farms. Communities and neighborhoods can also develop healthy food-growing habits.

a) Food Business Owners

Owners of hotels and restaurants can start vertical growth to get fresh, organic products for customers.

b) Urban Farmers

City farmers can make a business out of supplying products to eateries, supermarkets, or farmers’ markets.

c) Communities

Neighbors can start vertical farming and come together to form a community with a barter system.

d) Nonprofit Entities

If you want to supply fresh yields to a local soup kitchen or an NGO you run, vertical farms are ideal.

e) Individuals

If you just want to grow your own food for your family to friends, vertical farming is greatly beneficial.

Is vertical farming a profitable growth process?

Vertical farming has many positive effects on the environment. Giving back to nature can be a good thing, but will there be any motivation left to continue if it’s not a profitable venture?

The good thing about vertical grow systems is that they allow you to cultivate a large variety of crops all year round. You can even grow exotic plants that generally don’t grow in your location’s climate, especially if you use automation.

To produce the same amount of vegetables, the usage of raw materials in this farming system is 75% less than in traditional grow systems, while the power usage is 60 watts lower. For the same yield, it needs 10 times less land area compared to traditional farming.

In addition, this farming system can handle the major problem of losing crops due to weather conditions. Rain, drought, and floods can cause crop wastage, and so can root zone temperature fluctuations. All of these cause financial loss.

With indoor farming, air, light, heat, humidity, nutrient level, and water can be controlled. Another way to look at it is that crops can grow even in locations with adverse weather conditions or scarcity of natural resources.

Besides, vertical cultivation helps you get more crop cycles than conventional farming would allow. Plus, the yield is fresh, and the nutrient levels are high, with the least amounts of toxins. There’s always a high demand for such fresh, toxin-free fruits and veggies.

Since a vertical farm caters to a local market or eatery chains, acquiring crops is less costly due to low costs of transporting food. Automation systems, conveyor systems, indoor setups, etc., aren’t cheap. But the cost reduction in other areas and higher yield and sales make this farming system profitable.

How much more efficient is vertical farming?

The usage of high-efficiency light systems, low-carbon electricity, automation systems, etc., are all eco-friendly aspects of a vertical growing practice. Let’s take a look at how it is highly efficient.

a) All-Year Cultivation

The greatest benefit of this farming system is that it can beat nature’s effects to give you the best yield all year round. You can control and monitor the growing conditions, even for seasonal crops.

b) Space Efficient

Traditional farming needs acres of fertile land with ideal soil types. However, a vertical farm needs a small area of land and can even work without soil. The stackable growth system increases land productivity.

c) Minimal Water Usage

Vertical farming makes use of minimal amounts of water. This also results in reduced usage of nutrients. With proper recycling and reuse of water, there’s a minimization of waste, too.

d) Lower Fuel and Fertilizer Usage

Vertical growers do not resort to fossil fuels for sowing, fertilizing, or harvesting crops. When there is an automated crop growth system to control the resources and environment, pesticide use is reduced.

e) Reduced Transportation

Because vertical farmers mostly cater to local markets to keep the produce fresh, there is less transportation, and hence, less carbon footprint. It also reduces refrigeration of the yield.

f) Efficient Energy Usage

LED lights need significant power usage. But a vertical farming system can be set up to generate power. Excess power can be harnessed with advanced technology to be used anywhere in your business.

g) Less Labor Costs

The plant growth process in vertical farming does not need you to invest a lot in manual workers because it is less labor-intensive. Labor costs will only include sorting and packing harvests.

What can be grown in vertical farming?

Vertical farming can be started both indoors and outdoors. This system includes different types of farming systems, including skyscraper farms, recycled shipping container farms, and deep farms in tunnels and mine shafts. You can use them to grow different types of crops beyond just microgreens.

Types of plants you can grow in vertical farming systems include the following:

a) Leafy Greens

Lettuce, kale, chard, and collard greens are some of the best leafy greens to grow in vertical farming.

b) Herbs and Microgreens

Basil, mint, and chives are popular herbs that are easy to grow. You can also try their microgreens.

c) Gourd Family

Cucumber, zucchini, summer squash, and winter squash are ideal plants for vertical grow systems.

d) Peas and Beans

Vertical farmers can grow peas and green beans. Their plant varieties need very little monitoring.

e) Fruits

Melons, kiwis, and passion fruits are plants that can be grown in indoor farming without lots of care.

f) Hops

Hops are plants used in beer and as flavoring agents. Their production doesn’t need a lot of labor.

Are there any Downfalls to Vertical Farming?

The vertical plant production system may be a great investment in the future of humans and the environment. But, besides great benefits, it has its challenges and problem areas. Since in this method, plant production takes place inside buildings or container farms, natural pollination gets affected.

Modern technology provides solutions to problems of lighting, humidity, and even irrigation. So this growth process is heavily dependent on technology. Techniques like hydroponics, aquaponics, and aeroponics need applications of high-end technologies and machines for proper nutrient delivery.

Experts fear that machines and technologies may replace human services and labor. Urban farmers might pose competition for rural farmers who don’t use the same technology or irrigation solutions for crop yield. It’s time to pay attention to finding balanced solutions to these problems.

How much does it cost to start a vertical farm?

Like regular plant cultivation, vertical farming, too, has its expenses to take proper care of crops and find the best solutions for crop yield. Your initial investment will be in automation technology. You’ll have to pay attention to lighting, irrigation, monitoring, and energy efficiency solutions.

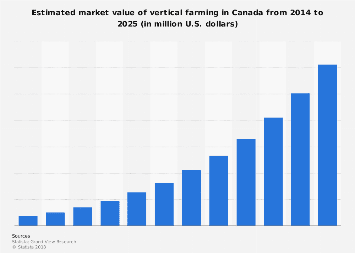

In 2020, the vertical farming business in Canada became a 530 million USD industry. This number is expected to gallop to 1.53 Billion by 2025. Small vertical farmers spend around $3.5 on energy for each square foot. This is about 12% of the total operating cost.

For large farmers, this cost is a little more than $8. This is about 25% of the total operation cost. Your business costs will include operating costs for labor, which is about $21 per square foot. You can expect to spend 6-13% of operating costs on nutrient solutions, seeds, growth medium, etc.

Accurate measurement of costs is hard to determine. But for every pound of yield, you can expect to spend $1.30 as upfront cost, $1.50 as growing cost, and $0.20 as transportation costs. So, the total cost should be about $3 for every pound of production using the vertical grow system.

How Our Automation Technology Helps Indoor Farming

The benefits of an automation system for a vertical grow design to produce healthy crops are undeniable. From taking care of irrigation and nutrient supply to monitoring light and water, everything can be done with the help of a good automation system.

A large number of indoor growers, including vertical farmers, trust the Climate Control Systems by Nebula Group. Their automation equipment and sensors focus on the monitoring and measurement of crops and yields so that you can keep track of the results of your efforts.

Their advanced sensors allow the automation of light, air, humidity, root zone temperature, EC, PH, nutrients, etc., in your farm. These include:

a) Fertigation System

Fertigation is an excellent method of irrigating and fertilizing a vertical plant growth arrangement. It allows you to customize feed formulas and reduce costs.

b) Climate Manager

Another excellent system is the Climate Manager that controls lighting and shading, temperature and humidity, misting and venting – all with the help of your phone or computer.

c) Ozone Pro

This water purification system collects water already used in irrigation and then sterilizes it. This purified water is reused in farming. Thus, it helps reduce environmental contamination, as well.

With the help of wireless control, you can manage the automation of everything from fertilizers to lighting remotely. All devices will remain connected with the help of IoT wireless control, and you can control and monitor all of them.

If you are a commercial grower looking to get a better crop yield and save money with the help of advanced automation, we can help you make your vertical farm a profitable venture.

Contact one of our automation engineers to see all the advancements on greenhouse technology can do for your next year in growing.